Boling Brothers - Meet the advertisers

Boling Brothers

words and Pics : Kleet Norris

Boling Brothers have been creating high quality hot rod parts, rolling chassis, frames, and complete hot rod builds for over ten years now. Early on they had humble beginnings, starting out in a small rented shop, the equivalent of a two-car garage. Where they are now in a fifteen thousand square foot building, that they own, which is in Lindsay, California. With owner Derrek Boling, designing the new parts and doing some of the fabricating. Along with longtime employee Jerrad Gilpin handling most of the chassis building and other fabrication, and Michael Rodriguez running the front desk and sales.

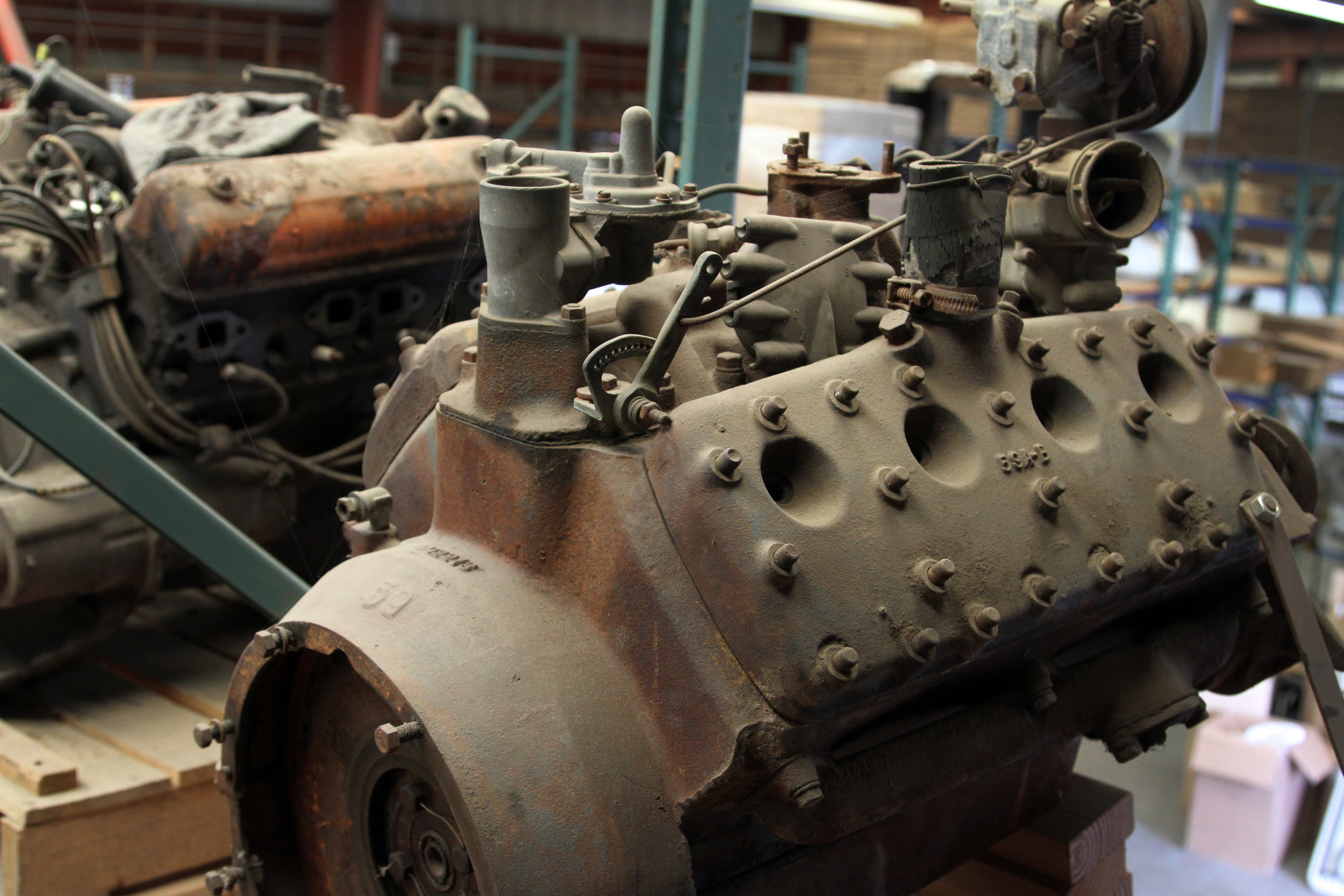

The main specialty of Boling Brothers is their custom made hot rod chassis for Model A Fords. They offer six different styles that hot rodders can choose from, either as a complete rolling chassis to just a bare frame; such as their traditional stock style chassis that allows a Model A body to be bolted directly to the frame with very minimal modifications, to their very low 5-12 frame which is for channeled Model A hot rods. The frame has a 5-inch kick-up in the front and a 12-inch kick in the rear getting the hot rod low to the ground. Boling Brothers can also build a stock style Model A chassis that has all the factory fender and running board mounts in the stock locations on the frame. For hot rods, other than Model A’s, they can also build a custom hot rod chassis to suite the customer’s needs.

Boling Brothers set quite a milestone for themselves in 2016, by building fifty fames for customers, in one year. For the new year, Derrek has ordered a new mandrel square tubing bender, so that their frame rails will be one solid piece from now on. Giving their chassis a cleaner, sleeker look and allowing them to offer more styles of hot rod chassis for their customers. They have also purchased an 80-ton hydraulic press, with plans on producing custom x-members for their frames as well as other hot rod parts.

Over the years, the guys at Boling Brothers have built several notable hot rods, in many styles. With their most popular build being their 1925 Dodge modified roadster, which spawned several clones after its debut. The Dodge was a unique take on hot rods at the time, it had a very low and short profile. With large 19” Ford spoke wheels that are as tall as the body, giving the hot rod a Go-Kart look. The Dodge now has a new owner, and resides in the Los Angeles area, where the owner takes it to several car shows in the area.

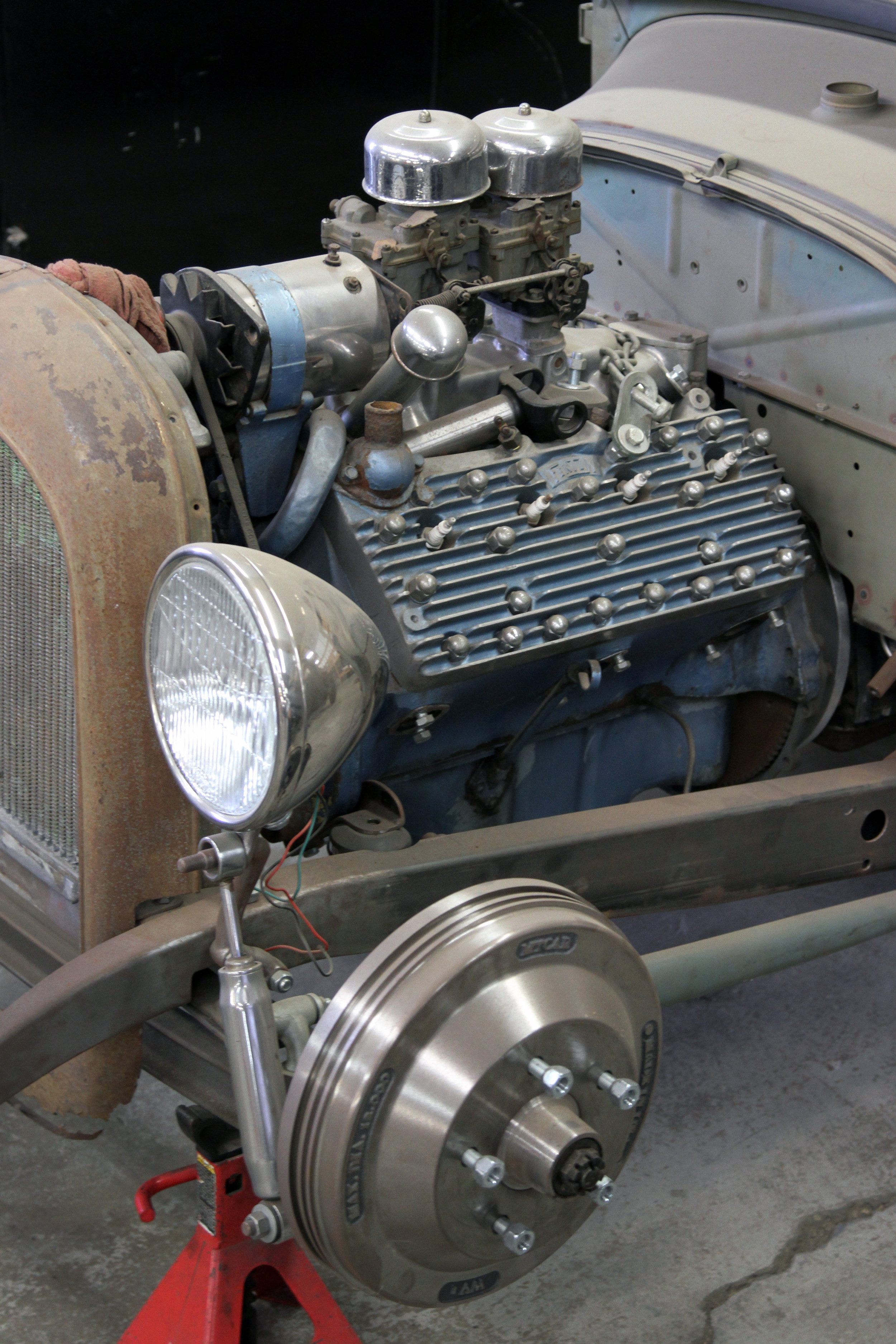

In 2011, Boling Brothers acquired the MT Car Products line of USA made reproduction Lincoln hydraulic brakes for hot rods and early Fords. The product line includes Lincoln backing plates, drums, hubs, and wire wheel supports. Since acquiring the company, Boling Brothers has expanded the line to include vented and chrome backing plates, as well as offering a complete Model A Ford hydraulic brake conversion kit, that has everything you’ll need to convert a Model A to hydraulic brakes, except for the steel brake lines.

With traffic being more hectic and congested, and people paying less attention while driving, being able to stop quickly in a hot rod is important. We wanted to test the stopping power for the three commonly used hot rod brakes while at Boling Brothers: The Lincoln brakes, the 1937-48 Ford hydraulic brakes and 1948-53 F-100 of F1’s as they are commonly referred to. We set up a 60mph to 0mph brake test for all three of the brakes on the same hot rod. The worst brakes out of the test were the 37-48 Ford brakes with an average stopping distance of 152 feet from 60mph to 0mph. The F-100 brakes were tested next, which performed a lot better than the 1940’s Ford brakes, with an average of 140 feet. Lastly the Lincoln’s were tested, and they stopped the best with an average of 134 feet, 6 feet better than the F1 brakes and 18 feet better than the ’40 Fords.

With the stop test concluded, what it will eventually come down to when choosing a brake system for your hot rod is availability. Currently the Lincoln hydraulic brakes are the only brakes that are being reproduced. While the other two brakes must be sourced through other methods such as Swap meets or eBay.

The guys at Boling Brothers, plan to continue to building hot rods, chassis, and quality hot rod parts. With no signs of stopping, they hope to beat their new goal. Which is to beat their fifty frames in one year record. Hopefully by the end of this year.